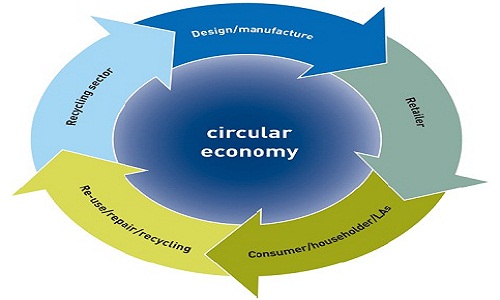

Many businesses have invested in recycling practices that seem like a natural starting point for more involved circular economy activities. Characteristics of a circular economy suggest that more fundamental shift required to decouple growth from finite resources and move to a circular development path.

As per the circular economy, there is a fundamental shift in the way resources, energy and information flow through our economy. A key characteristic of this framework is that products and components remain at their highest levels of integrity and performance.

The perception is that a circular economy is just ‘recycling on steroids’ - recycling more stuff, and doing it a bit better. This confusion is understandable. Since the 1970s, recycling has become synonymous with ‘doing good.’ What’s more, many businesses have invested in recycling practices that seem like a natural starting point for more involved circular economy activities. However, the characteristics of a circular economy - and existing research - suggest that returning a product to the material level would be ‘the loop of last resort,’ with a more fundamental shift required to decouple growth from finite resources and move to a circular development path.

The real opportunity

Economic analysis conducted by the Ellen MacArthur Foundation and McKinsey & has demonstrated how, in a circular economy, greater value can be obtained by operating in the ‘inner loops’ of a technical cycle. Activities such as sharing, service, maintenance, refurbishment and remanufacturing preserve the integrity of a product. We often hear about how a company has recovered a product and then processed the materials so they can be used as a resource. But think about it - by returning a product to its constituent materials you lose all the energy, labour and expense that went into creating it in the first place. In some cases, the recycling process may even be more costly than extracting virgin resources. This can severely undermine recycling efforts - in the current context of depressed commodity prices.

Consider that recycling is a generic term, with a range of possible nuances. More often than not, emphasis is placed on post-consumer recycling. This shifts responsibility to the public, but also misses the point. A significant amount of waste is generated at the extraction and production phase when making new products - another reason to suggest that the real opportunity might lie elsewhere.

Real opportunities for higher levels of valorisation exist in the ‘inner loops’ of a product cycle and it is here that businesses, users and governments can really start to see the benefits of a circular economy. In fact, studies have suggested that seizing these types of value creation opportunities wouldn’t just achieve a one-off dent in resource demand, but could actually change the run rate of required material intake. The pursuit of this circular economy development path could see European GDP increase as much as 11 per cent by 2030 and 27 per cent by 2050, compared with 4 per cent and 15 per cent in the current, linear development scenario.

Recycling, a necessity

At some point products and components will break down, and it won’t be possible or sensible to keep them in service any longer. At this point, a recycling option will be necessary. Even then, we need to rethink the process. Widespread legislation on recycling rates has encouraged businesses to look to end-of-pipe solutions, and whilst these are often commendable, they naturally revolve around making do with the scraps at hand. Frequently this means dealing with stuff designed in a linear, take-make-dispose mindset. Toxic materials, integrated design and irreversible adhesives are all design choices that can get in the way of positive and scalable recycling activities.

The ‘New Plastics Economy’ report, released at the World Economic Forum, revealed the scale of material leakage from today’s plastics system. Even when we can recover dispersed materials, current recycling techniques rarely preserve all the material. For example, around 80 per cent of recycled PET bottles are turned into polyester fibers for carpet, clothing and other non-packaging applications. With paper recycling, fibers diminish after six or seven cycles, and they can no longer be used for paper production. Important progress is being made, but this still represents significant material losses over time. To truly optimise resource flows, future pathways should be considered at the design phase. In the Towards the Circular Economy report series, this is summarised by ‘the power of pure inputs.’

The circular economy gives us a chance to create a new story for the global economy. Recycling has a place within that story, but rather than simply eking out our materials a bit further, a systemic shift based on circular economic principles offers greater business opportunity, and the potential to decouple growth from finite resource inputs.

Address: 40 Hoa Hong St, Ward 2, Phu Nhuan , HCMC 70000, Vietnam.

Address: 40 Hoa Hong St, Ward 2, Phu Nhuan , HCMC 70000, Vietnam. Phone: (+84) 2835 178 107 . WhatsApp / Viber : +84908839043 - Fax: (+84) 2835 178 106

Phone: (+84) 2835 178 107 . WhatsApp / Viber : +84908839043 - Fax: (+84) 2835 178 106 Email: info@namphonggroup.com

Email: info@namphonggroup.com